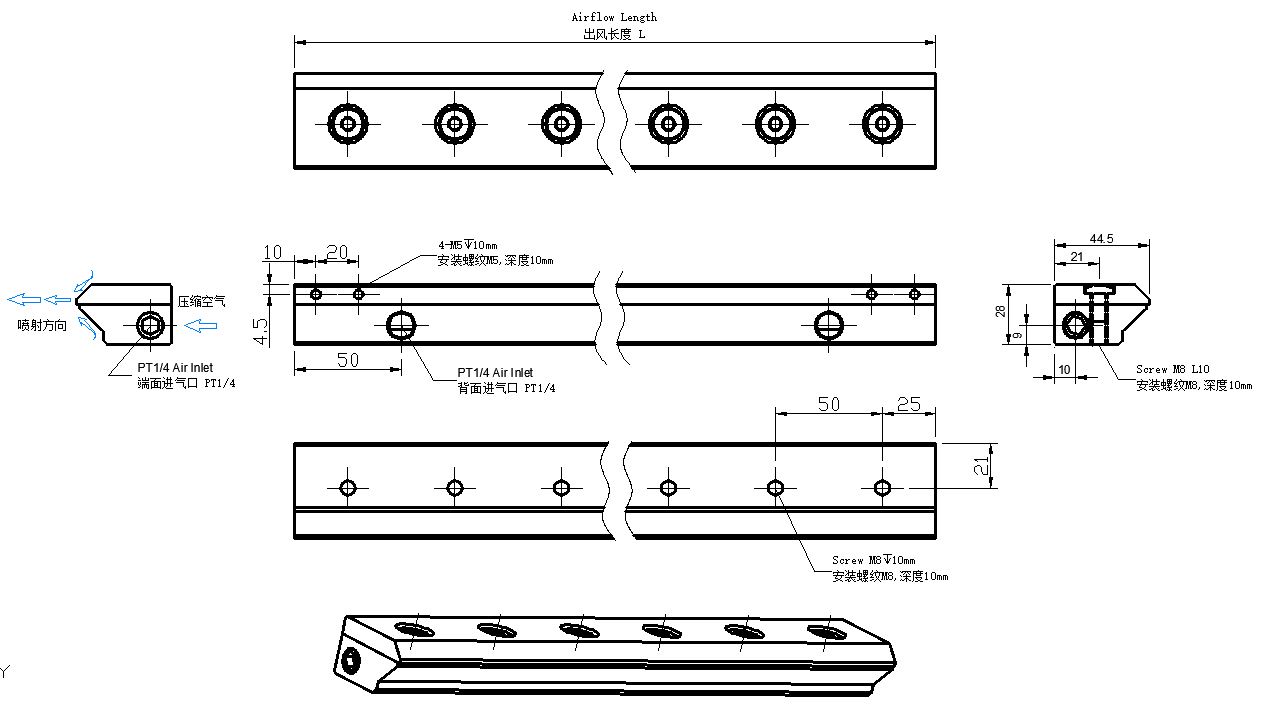

It is thinner than the F-type super air knife, with a thickness and width of 28*44.5mm. The entire length can be up to 2000mm. It can be spliced into

Specifications and parametersSUNAIR Super Air Knife It provides uniform laminar airflow over the entire length, with powerful hitting power and lower cost of use. It is designed to significantly reduce the use of compressed air while drawing in ambient air at a 40:1 ratio for air amplification. Compared with other jet devices, it saves energy and reduces consumption, and the noise level is greatly reduced. Available from stock in lengths from 50mm to 2000mm. If longer, you can use a splicing kit to extend the air knife to the required length. The length of 2 spliced pieces can reach 4000mm.

A variety of materials are available, including aluminum, type 303 stainless steel, type 304 stainless steel, type 316 stainless steel, PVC, POM and PVDF to meet all customer application needs. Custom sizes and materials available. SUNAIR air knives provide an effective method of cleaning, drying and cooling and can be used as an environmental isolation or air curtain.

SUNAIR super air knife principle:

The compressed air enters the high-pressure chamber of the air knife through the air inlet (1). The airflow passes through the narrow, thin nozzle (2) and forms a balanced airflow sheet along the length of the air knife. Since the compression ratio of the chamber (3) to the high-pressure airflow is 40:1, the airflow velocity loss is minimal and the pressure is greater, thus producing an airflow sheet with strong impact force and minimal shear force.

Traditional air blowing application products have many disadvantages, such as: the blown air flow is uneven; the compressed air consumption is very large; although it has strong impact force, the noise level is too high, seriously affecting the health of on-site operators; electric energy-powered products Inflatable products often require frequent maintenance and have short service life.

application:

1- Dry the parts after cleaning

2- Plate cleaning in strip mills

3- Conveyor belt cleaning

4- Part or component cooling

5- Dry or clean the roll

6- Environmental isolation or air curtain

7- Blow off before painting

8- Air blowing operation for bag opening/filling

9- Scrap removal during production

advantage:

1- Minimum air consumption - cost savings

2- 40:1 air amplification

3- Low noise - less than 69 dBA for most applications

4- Uniform airflow throughout the entire length

5- Adjustable intake pressure changes impact force and flow rate

6- No moving parts - Maintenance free

7- Easy to install - Compressed air inlets on both ends and back

8- Compact, sturdy and easy to install

Material selection:

Type 303 Stainless Steel: This is the most common grade of stainless steel. It has good strength and is best suited for mildly corrosive environments. In its gasketless form, it can withstand temperatures up to 427°C.

Type 304 Stainless Steel: Certain applications require better strength and corrosion resistance than Type 303 stainless steel. Type 304 stainless steel has excellent corrosion resistance and better strength properties and is also used by food manufacturers. It can withstand temperatures up to 427°C.

Type 316 Stainless Steel: Certain applications require better corrosion resistance than Type 304 Stainless Steel. Type 316 stainless steel offers excellent corrosion resistance, better strength properties and resistance to pitting corrosion. These factors are important to manufacturers of food, pharmaceutical and surgical products who need to minimize metal contamination. It can withstand temperatures up to 427°C.

POM polyacetal resin: POM air knife has high mechanical strength and rigidity, high fatigue strength, environmental resistance, and good resistance to organic solvents. POM air knife is used in mildly corrosive solvent applications and has a maximum temperature resistance of 60° C.

PVC polyvinyl chloride: PVC air knives are mainly used in chemical corrosion-resistant applications. They are low-priced, flame-retardant, chemical-resistant, high wear-resistant and have good electrical insulation. It can be used in optoelectronic production equipment, with a maximum temperature resistance of 60°C.

PVDF (Polyvinylidene Fluoride): PVDF offers exceptional strength and resistance to UV rays, inorganic chemicals, solvents, ozone, weather, fungi, chlorinated hydrocarbons, highly corrosive acids, weak alkalis, and salts. The PVDF Super Air Knife uses a gasketless form, 316 stainless steel pipe plugs and titanium screws to withstand harsh environments. The PVDF Super Air Knife is suitable for manufacturing processes involving electroplating, solar cells, lithium-ion batteries, transfer of acids and corrosive chemicals, brine, solvent recovery, semiconductors and medical devices. It can withstand temperatures up to 135°C.

Air knife accessories:

1- Universal Air Knife Mounting Bracket: It can be mounted on the top or bottom of most air knives (Super Air Knife, Ion Air Knife, Standard Air Knife and Full Flow Air Knife). The universal air knife mounting bracket features durable stainless steel construction and is suitable for a variety of industrial applications.

2- Non-standard air knife installation bracket: We can design special air knife brackets for customers according to their requirements, including super air knife, ion air knife, TA precision air knife, etc. The customer needs to provide the installation space size, which must be According to the usage requirements, air knife model, etc., our professional technical staff can design for customers.

3- Air knife duct kit: Super air knives 600mm or longer must have compressed air supplied at multiple inlets on the air knife. An air knife duct kit prevents you from finding inappropriate fittings or using undersized air supply lines. We offer appropriately sized compressed air hose or pipe, as well as fittings for connecting bottom or end compressed air inlets for better performance. Pipe kits for aluminum Super Air Knife, including a pressure gauge to monitor the pressure at the Super Air Knife, which is an indication of normal air supply. They also include PU hoses and tee fittings. Pipe kit for stainless steel super air knives includes stainless steel fittings, also suitable for PVC, PVDF super air knives.

4- Coupling Bracket Kit: Certain applications require a longer Super Air Knife than our 2000mm length. Splice bracket kits are available to connect two Super Air Knives together. The splice kit includes two rigid plates and assembly screws. Both the bottom bracket plate and the top bracket plate have through holes for mounting threads. All models include stainless steel screws.

To provide you with professional solutions