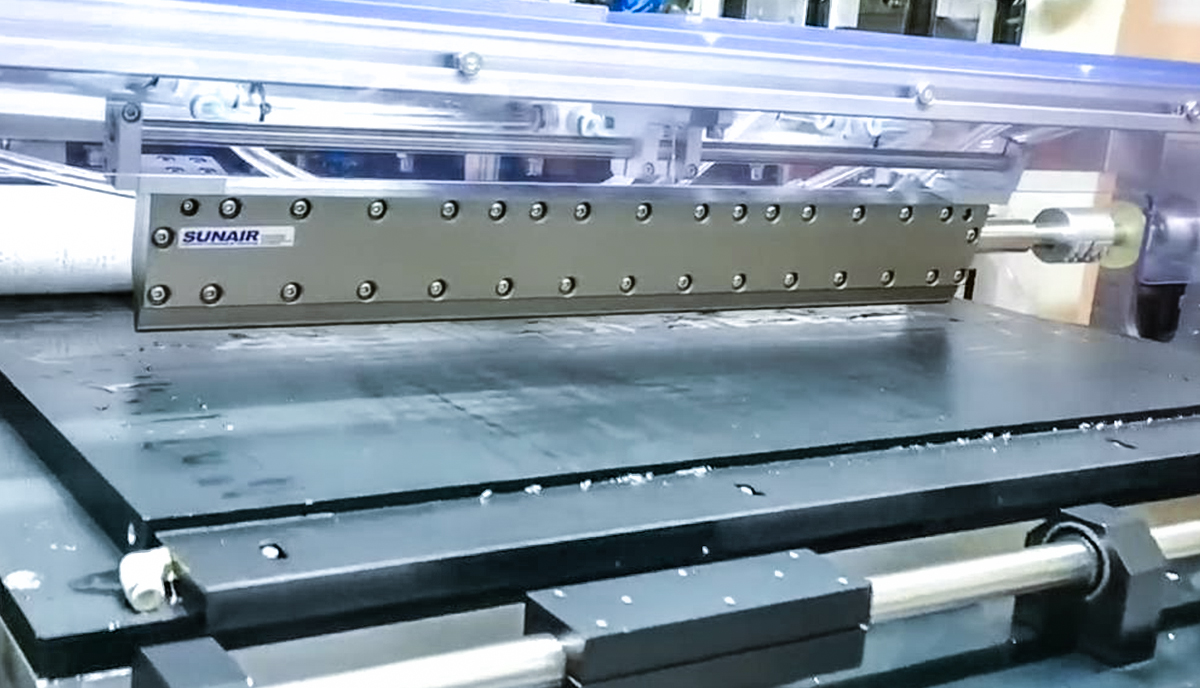

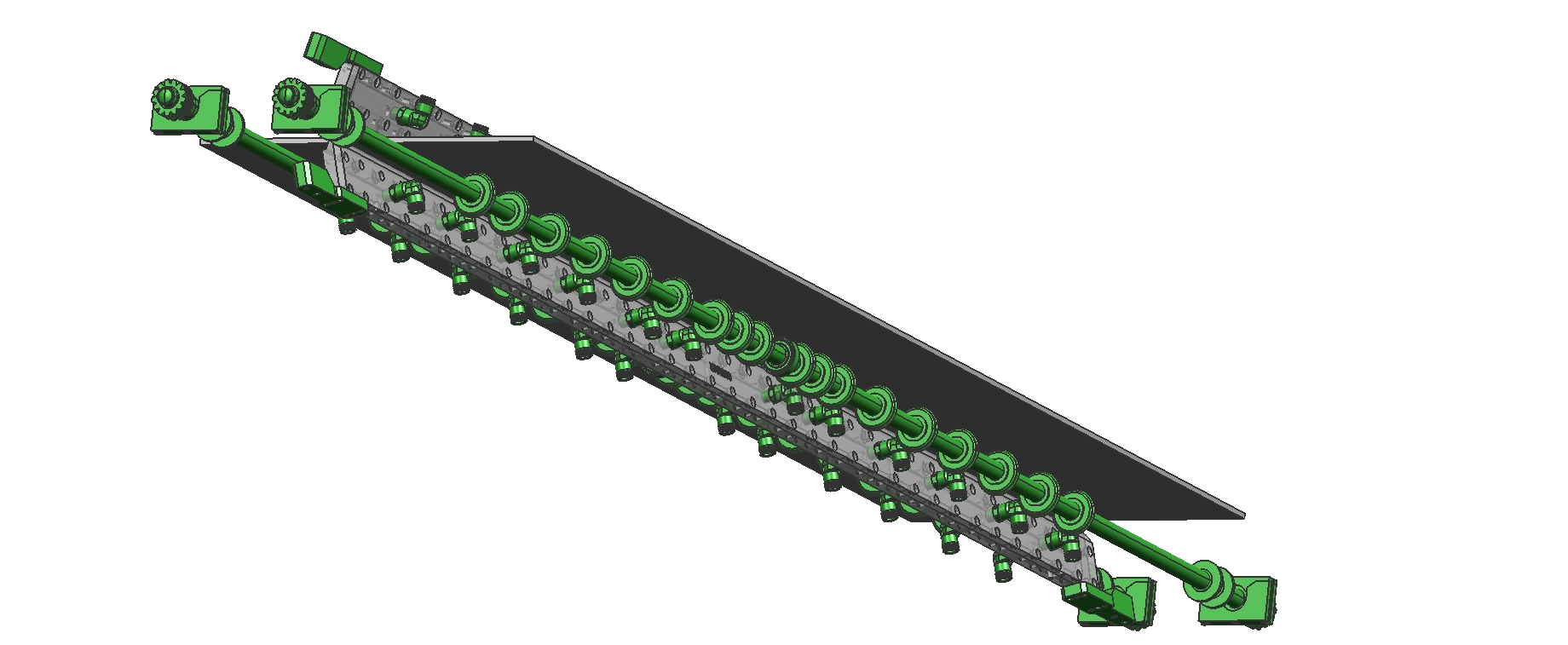

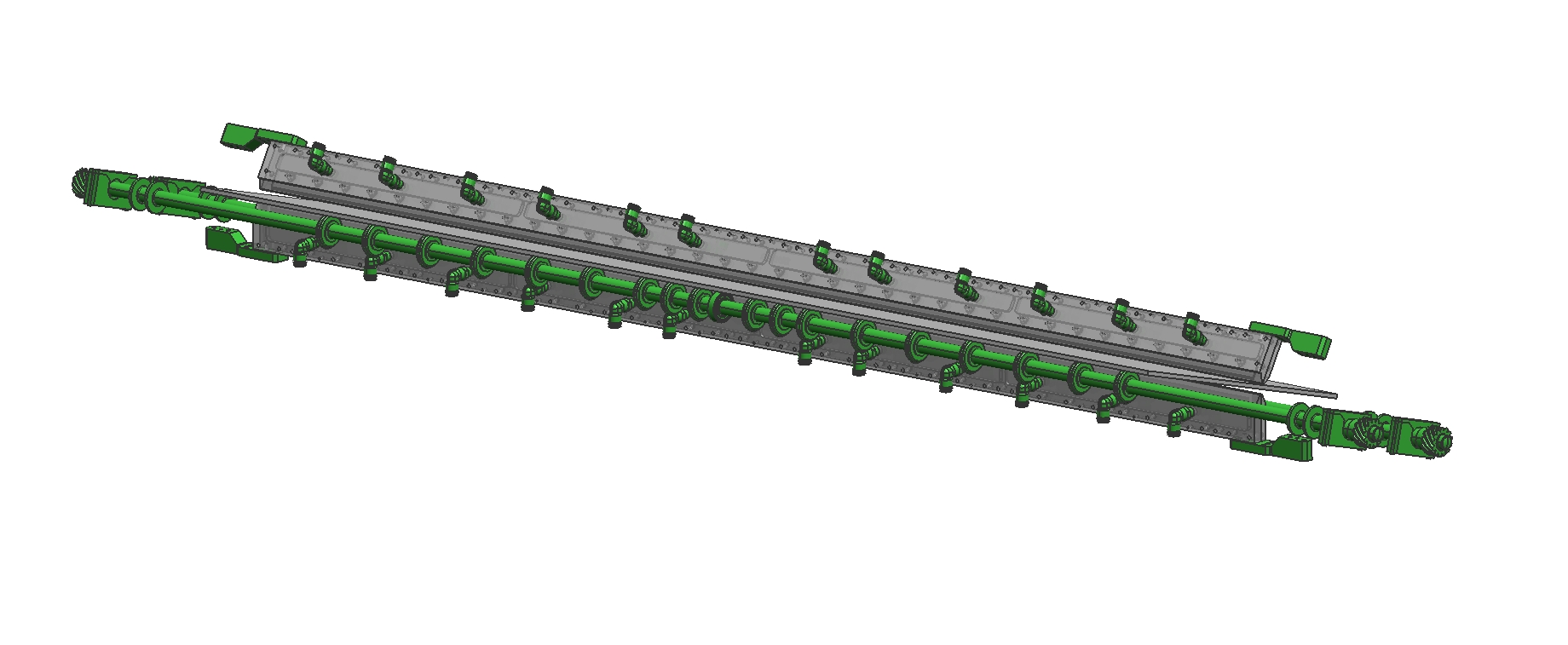

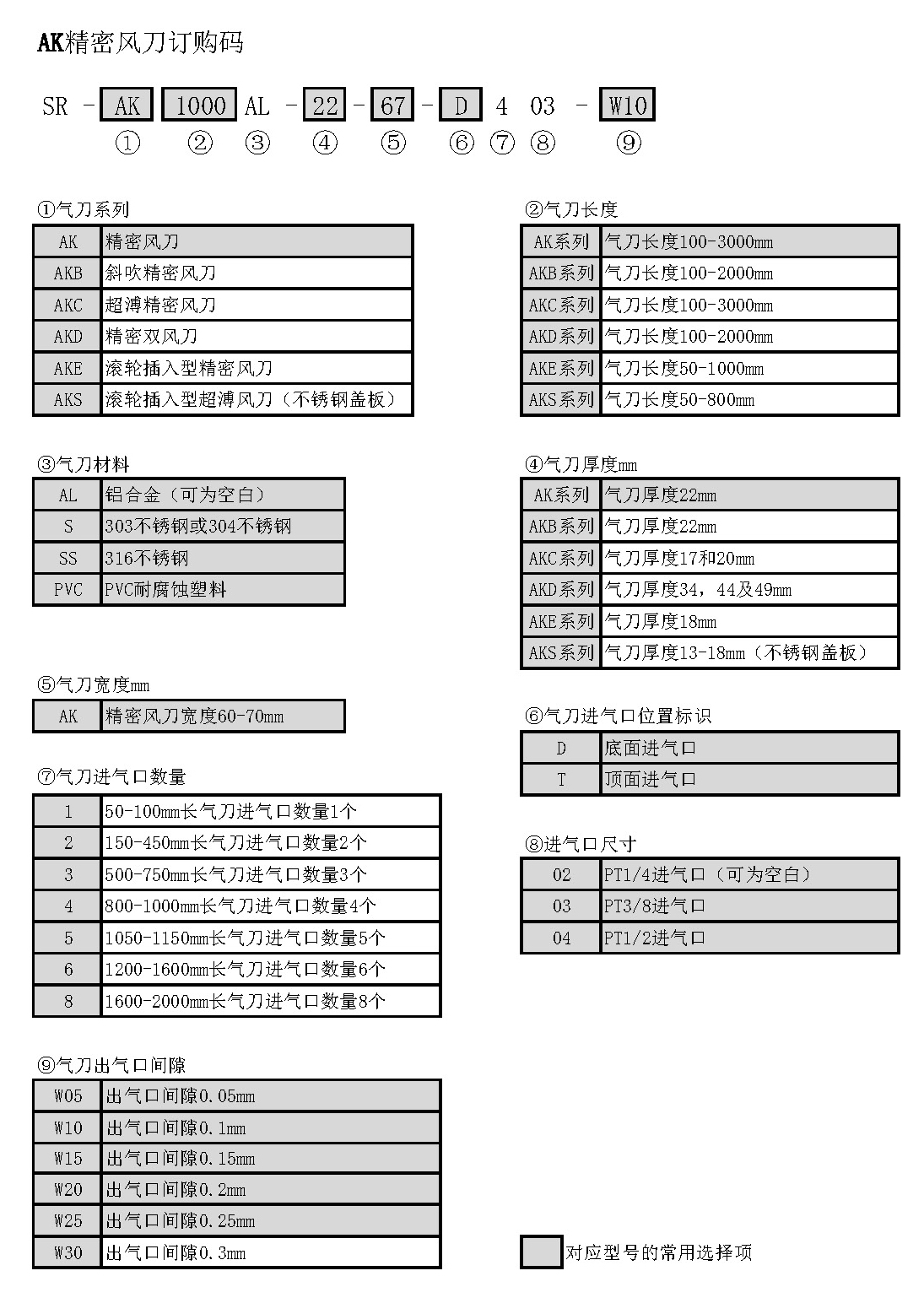

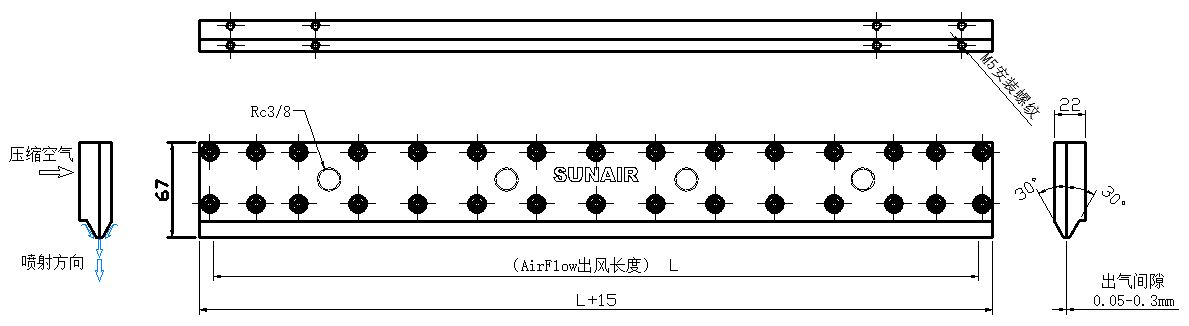

Standard type: thickness and width size 22*67, full range spraying, amazing air flow uniformity, efficient water removal performance, used for water r

Specifications and parametersAK Air Knife It provides uniform laminar airflow over the entire length, with powerful hitting power and lower cost of use. It is designed to significantly reduce the use of compressed air while drawing in ambient air at a 40:1 ratio for air amplification. Compared with other jet devices, it saves energy and reduces consumption, and the noise level is greatly reduced. The maximum production length is 2500mm.

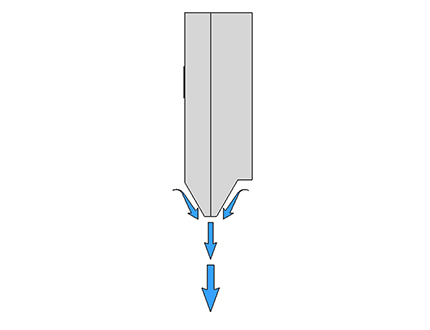

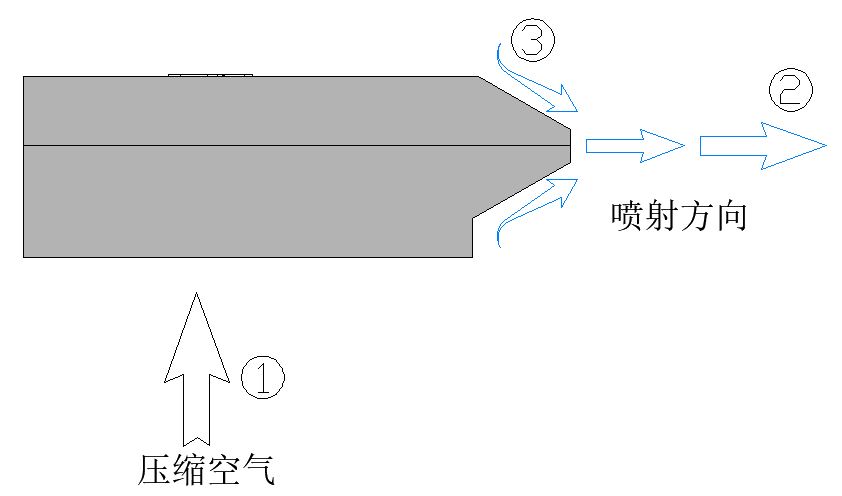

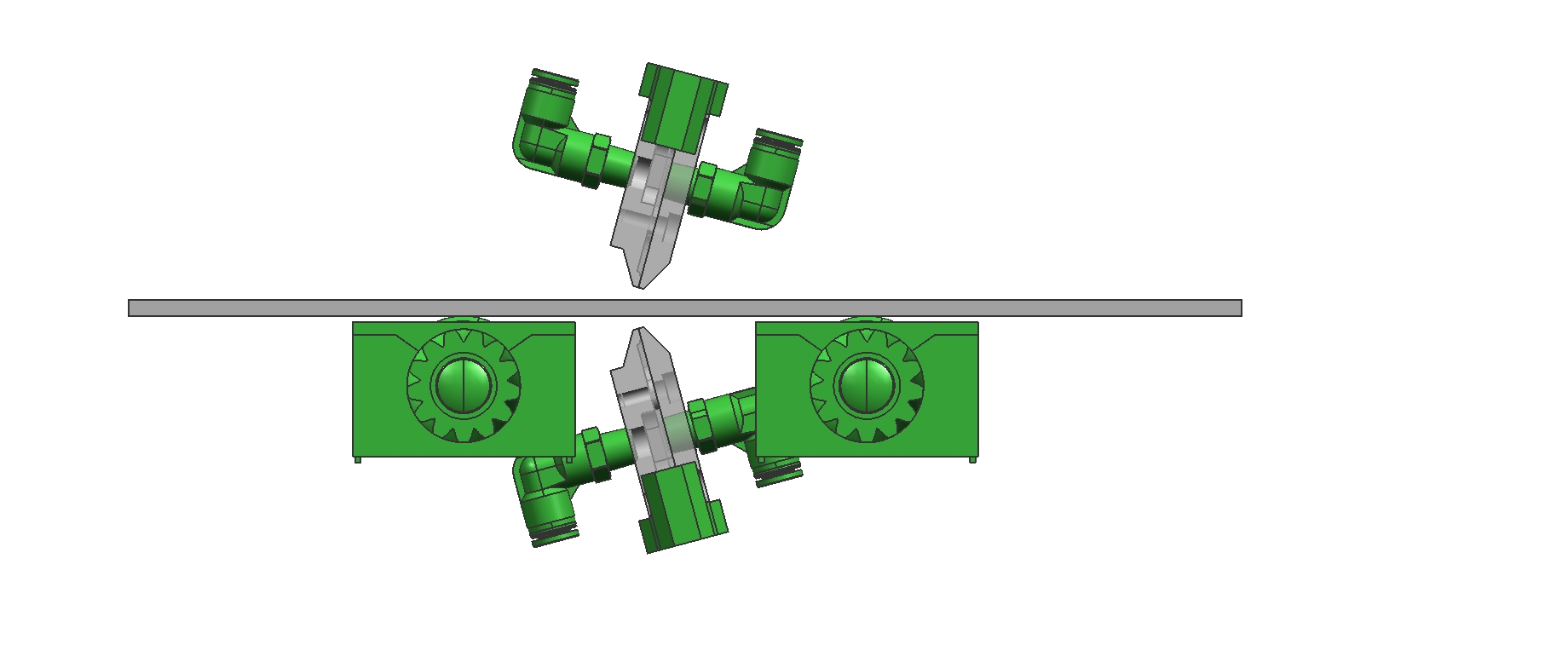

Wind knife principle:

The compressed air enters the interior of the air knife through the air inlet (1) , and re-compresses the air flow multiple times through the internal chamber. Finally, after passing through the thin air knife edge (2) , a balanced air flow sheet is formed in the length direction of the air knife. , the air knife edge is equipped with a special angle 3. The air flow drives the air around angle 3 to spray together, achieving an amplification effect of 40:1. Since the internal chamber of the air knife compresses the air flow multiple times, the loss of air flow speed is minimized, while the pressure Larger, thus creating an airflow sheet with strong impact force and minimal shear force.

Traditional air blowing application products have many disadvantages, such as: the blown air flow is uneven; the compressed air consumption is very large; although it has strong impact force, the noise level is too high, seriously affecting the health of on-site operators; electric energy-powered products Inflatable products often require frequent maintenance and have short service life.

application:

1- Water removal and drying of FPD glass substrate

2- Plate cleaning of strip mill

3- Dewatering and drying of conveyor belt products

4- Part or component cooling

5- Roll drying or cleaning

advantage:

1- Spray the entire strip and the entire range

2- 40:1 air amplification

3- Uniform airflow throughout the entire length

4- Low Noise - Less than 69 dBA for most applications

5- Adjustable air intake pressure changes the impact force and flow rate

6 -No moving parts- Maintenance free

7- Compact, sturdy and easy to install

Air knife length selection:

1- Usually, the length of the air knife is selected according to the basic width of the glass. Normally, 15-20mm should be added to one side of the width of the glass substrate. For air knives with a length exceeding 1000mm, 30-50mm should be added to one side.

2- The selection of the length of the air knife should also consider the installation method of the air filter knife. If the air knife is installed at a certain angle in the direction of movement of the glass substrate, the length of the air knife should be greater than the size after installation at an angle.

Material selection:

Aluminum : Aluminum Super Air Knives are suitable for use in a variety of environments where corrosion or contamination factors are not present. The aircraft-grade aluminum construction with plastic spacers is durable and suitable for general use. The stainless steel screws used are corrosion-resistant. Its internal gaskets can withstand temperatures up to 82°C. If you need to withstand higher temperatures, the air outlet gap can be directly processed on the air knife, without a gasket, and can withstand high temperatures of 150°C.

Type 303 Stainless Steel: This is the most common grade of stainless steel. It has good strength and is best suited for mildly corrosive environments. In its gasketless form, it can withstand temperatures up to 427°C.

Type 304 stainless steel: Certain applications require better strength and corrosion resistance than Type 303 stainless steel. Type 304 stainless steel has excellent corrosion resistance and better strength properties and is also used by food manufacturers. It can withstand temperatures up to 427°C.

Type 316 Stainless Steel: Certain applications require better corrosion resistance than Type 304 stainless steel. Type 316 stainless steel offers excellent corrosion resistance, better strength properties and resistance to pitting corrosion. These factors are important to manufacturers of food, pharmaceutical and surgical products who need to minimize metal contamination. It can withstand temperatures up to 427°C.

PVC polyvinyl chloride : PVC air knives are mainly used in chemical corrosion-resistant applications. They are low-priced, flame-retardant, chemical-resistant, high wear-resistant and have good electrical insulation. Can be used in optoelectronic production equipment, with a maximum temperature resistance of 60 °C.

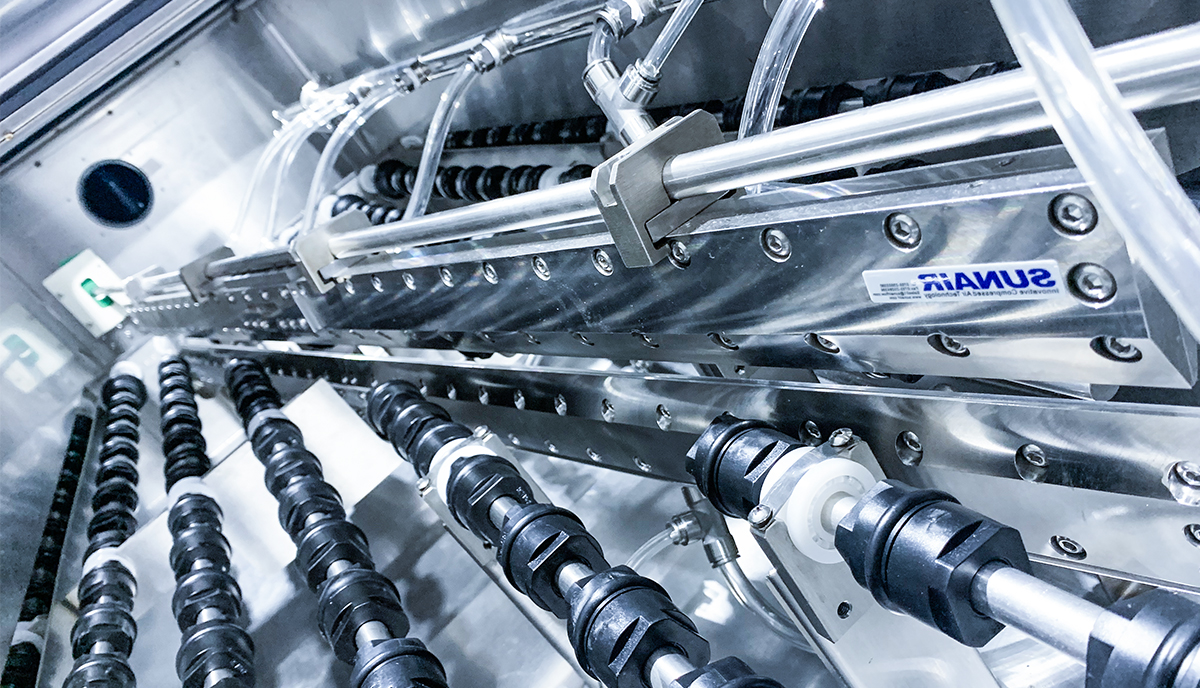

Air knife installation:

There are usually threads on the top of the air knife to lock the bracket. Since the blowing direction, angle and height of the air knife are easy to adjust, the bracket needs to be adjustable in all directions.

To provide you with professional solutions