The FB type ion air knife has a more compact structure. The ion generator and the ion air knife are designed in an integrated manner. The dust removal

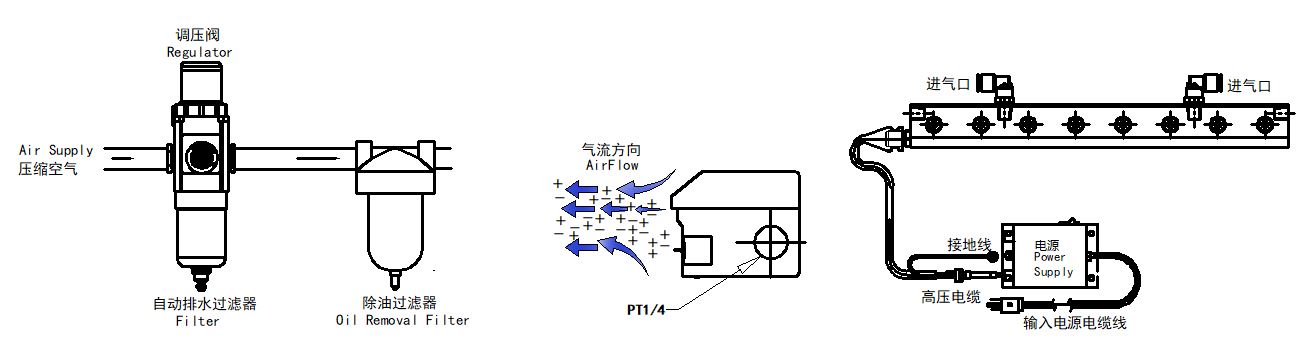

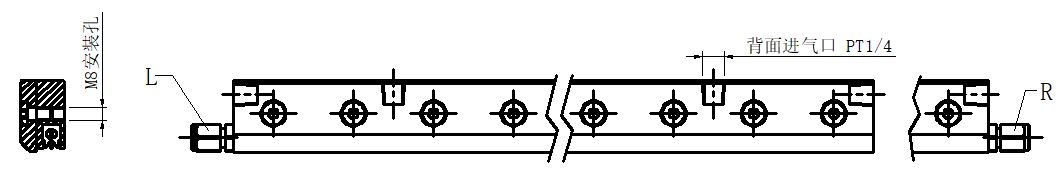

Specifications and parameters1. Installation diagram

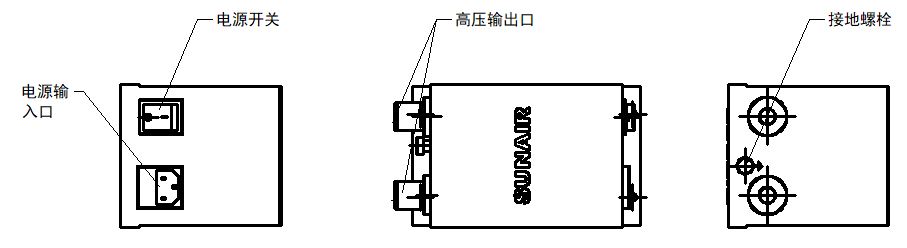

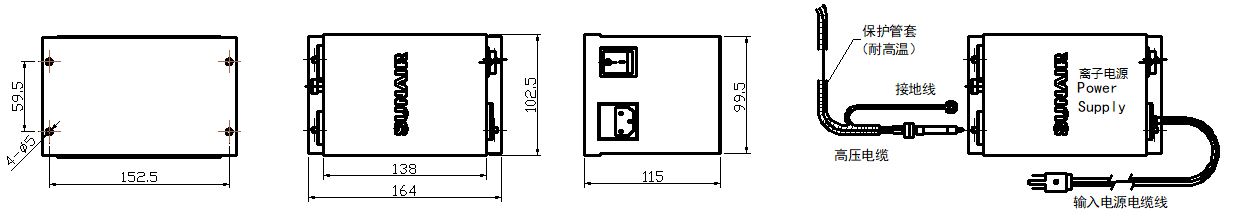

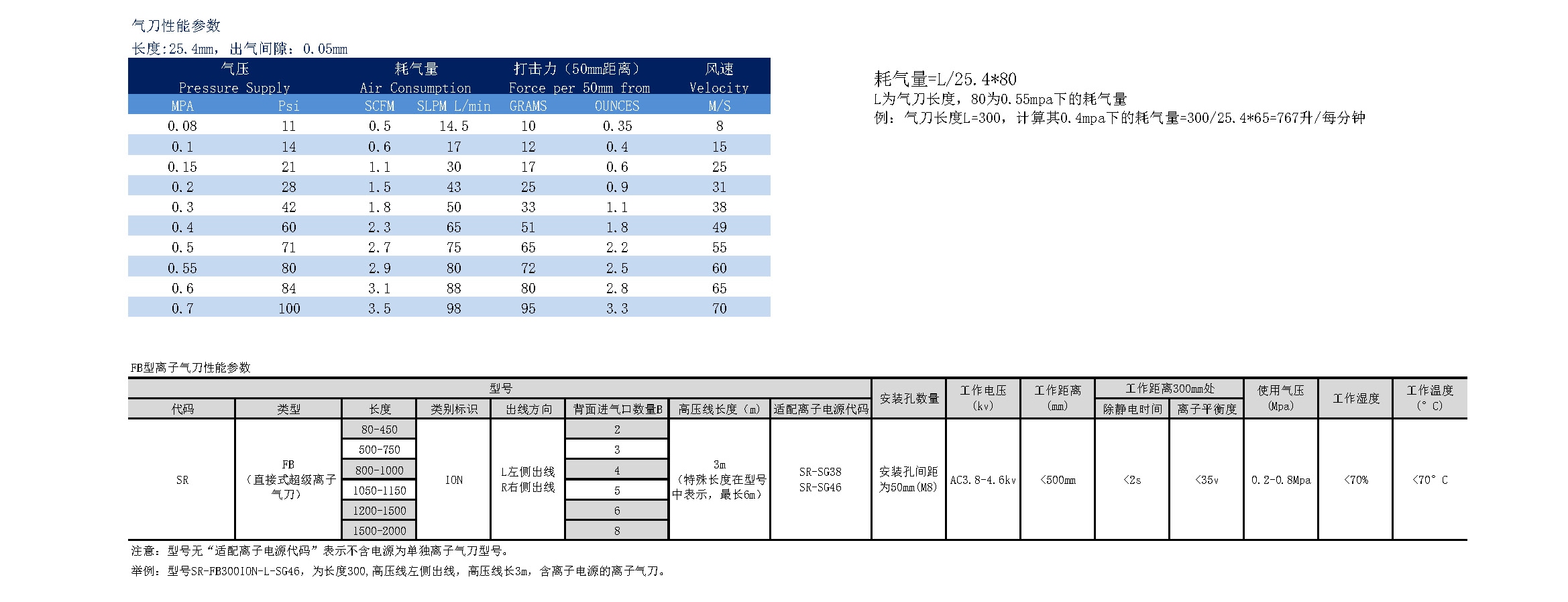

2. Performance parameters and drawings of ion power supply:

Power supply model: SR-SG38

Input voltage: 220V/50Hz

Output voltage: 3800V

Input current: 130mA max

Output current: 3.5mA max

Greater power: 20W

High voltage output port: 2

3. Number of air inlets and size of trachea

We should select the number of air inlets and the size of the air pipe according to the length of the ion air knife. If there are too few air inlets and the size of the pipe is too small, the ion air knife will not get enough air supply and the blowing performance will not be up to par. to our usage requirements. Let's take the standard outer diameter 10mm and 12mm air pipes as an example. The required number and length of air inlets are compared in the following table.

wAir flow length 250mm 10mm air pipe Number of air inlets 1

wAir flow length 350mm 12mm air pipe Number of air inlets 1

For example: If the length of the ion air knife is 1000mm, the number of air inlets is 4 when using a 10mm air pipe, and there are 3 air inlets when using a 12mm air pipe.

4. Compressed air supply

The positions of the air inlets should be chosen to be evenly distributed along the entire length of the air knife to maintain balanced air flow. We also provide universal pipe fittings (sold separately) for connecting to the same ion gas.

Compressed air is used to separate impurities such as dirt, water and oil from the air through the use of suitable filtration. The ion air knife will run for a long time without clogging. Use a 15 micron or higher precision self-draining filter in the compressed air supply to separate moisture, impurities and dirt in the air. In order to solve the problem of oil in the air, an oil removal filter should also be used.

wThe filter should be installed near the ion air knife, within 5 meters.

wThe filter should be a medium or large model with a thread size of the inlet and outlet pipes larger than PT3/8 to prevent flow restriction.

wThe size of the air inlet and outlet of the solenoid valve used to control the on and off of compressed air should also be larger than the PT3/8 pipe thread to prevent flow restriction.

5. Installation and fixation

Note: The ion air knife and power supply cannot be used in flammable and explosive places.

1. The back of the ion air knife has an M8 thread for installation. It can be fixed at any working position or can be fixed with a compressed air hard pipe.

instructions:

2. After the ion air knife is installed at a certain position, the static electricity of the material at that point is eliminated. If the treated material is subject to additional friction during transportation or movement, it may form another type of static charge, and then another type of static charge may need to be added. A set of ion air knives for static elimination.

3. Screw the power cord on the ion air knife into one of the output ports of the power supply, and tighten the bolt connecting the ground wire to the power supply with a nut. Make sure the grounding is good. This power supply has an input voltage of 220V and the plug of the input voltage cable. It is a 3-prong design, one of which is the ground wire. Make sure it is properly grounded. Do not turn on the power until all connections are complete.

4. It is recommended that the cable connecting the ion air knife and the power supply be shielded in a plastic casing. Since this cable is a high-voltage wire, it cannot be routed together with the cables of other electrical appliances in the equipment without a plastic casing shield.

6. Precautions for using power supply

1. To ensure that the input power voltage is stable, it is necessary to add a voltage stabilizing device.

2. The power supply should not be used in explosive or flammable areas.

3. It must be well grounded, otherwise the power supply will be damaged.

4. Turn on the power switch after completing all connections.

7. Fault diagnosis

1. The ion power supply must be properly grounded, otherwise it will not work properly, and there will be high-voltage impact, which will damage the power supply and the ion air knife.

2. If the air flow rate of the ion air knife decreases, you can check the pressure at an unused air inlet by installing a pressure gauge. The reason for the decrease in air flow rate is directly related to the air supply. You should first check the air source. Pressure and flow, then check the diameter of the air inlet pipe, the number of air inlets, the model size of the filter, the allowed maximum flow rate of the solenoid valve, etc. Pneumatic components that cannot limit flow are not allowed.

8. Maintenance

If dirt blocks the ion air knife, it can be disassembled and inspected. The ion air knife is composed of a generator connected to the air knife. The air knife is divided into two parts: the upper part and the lower part. The upper part is the air knife cover. After unscrewing the bolts, you can open the cover. Check the dust, dirt and oil film in each air channel in the air knife, clean them, and then remove the cover. Cover the plate back and tighten the bolts in sequence from one end to the other.

Keeping the electrode needles of the ion generator free of moisture and dirt is very important for its performance and service life. The discharge needles should be cleaned regularly for 3-6 months with a soft brush. Do not use any tools that will bend or damage the discharge needles. Note Always turn off the power supply when cleaning electrode needles.

| 2006/42/EC Machinery Directive |

| 2014/30/EU Electromagnetic Compatibility Directive |

To provide you with professional solutions