Full 304 or 316 stainless steel material, corrosion resistance, stainless steel chassis cabinet cooler is very suitable for use in harsh industrial en

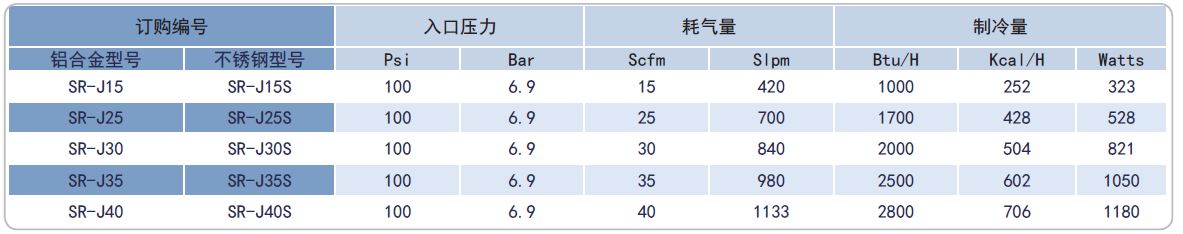

Specifications and parametersUNAIR stainless steel chassis cabinet cooler is very suitable for use in harsh industrial environments. Made of all 304 or 316 stainless steel.

SUNAIR cabinet cooler is different from expensive Freon air conditioners. SUNAIR cabinet cooler uses vortex tube, which uses compressed air to generate cold air. There are no moving parts and no maintenance. SUNAIR cabinet cooler installation and removal can be completed in minutes and maintains the dust-proof rating of the electronic enclosure. All cabinet coolers comply with CE standards. They are a low-cost, reliable method of cooling and purifying electronic control cabinets or enclosures.

What is the SUNAIR chassis cabinet cooling system?

SUNAIR cabinet cooler is a low-cost, reliable method of cooling and purifying electronic control cabinets and chassis. It is simple to use and easy to install. It is available in a variety of cooling capacity models and is suitable for large and small chassis and cabinets. SUNAIR chassis cooler uses a vortex tube to generate cold air from compressed air. It has no moving parts and is maintenance-free. Enclosure coolers provide cooling for electrical cabinets and enclosures, eliminating electronically controlled downtime caused by heat, dirt and moisture.

Why choose SUNAIR chassis cabinet cooler?

When the electronics inside the control cabinet overheat, the machine may shut down due to overload and tripped circuit breaker or thermal damage to the circuit board. Unreliable cooling methods such as fans, heat exchangers, refrigeration air conditioners and heat pipes are prone to failure due to mechanical wear and clogged filters.

SUNAIR cabinet coolers provide cool air to large and small control panels and are maintenance-free. They have no moving parts that wear out. All cabinet coolers comply with CE standards.

advantage

1- No moving parts and maintenance free

2- Create positive pressure inside the chassis and cabinet so that dust cannot enter

3- Quiet operation

4- Only compressed air is required, no electricity is required

5- Long-term operation and stability

6- Can be used on outdoor and offshore working platforms

7- Can be used in extremely harsh environments

Application areas

1- Programmable controller

2- Line control cabinet

3- Motor control center

4- Relay panel

5- CNC system

6- Modular control center

7- Monitor system cooling

8- Computer room cabinet refrigeration

9- Cool down the laser lens

It happens when you least expect it. High temperatures can burn out the electronics that control the machine, causing false readings, tripping, or burned-out circuit boards. Cooling electrical cabinets can eliminate these problems.

Opening the panel door and pointing the fan at the circuit board is a bad idea:

1- This is a safety violation and creates a risk of electric shock to personnel

2- Fans blow hot, humid, dirty air onto electronic devices

3- Minimal cooling effect

4- Since the environment is still hot, the circuit problem is likely to reoccur

To provide you with professional solutions