Lubrication is a type of lubrication used in metal processing, i.e. semi-dry cutting. Lubrication is lubrication, where compressed gas (air, nitrogen,

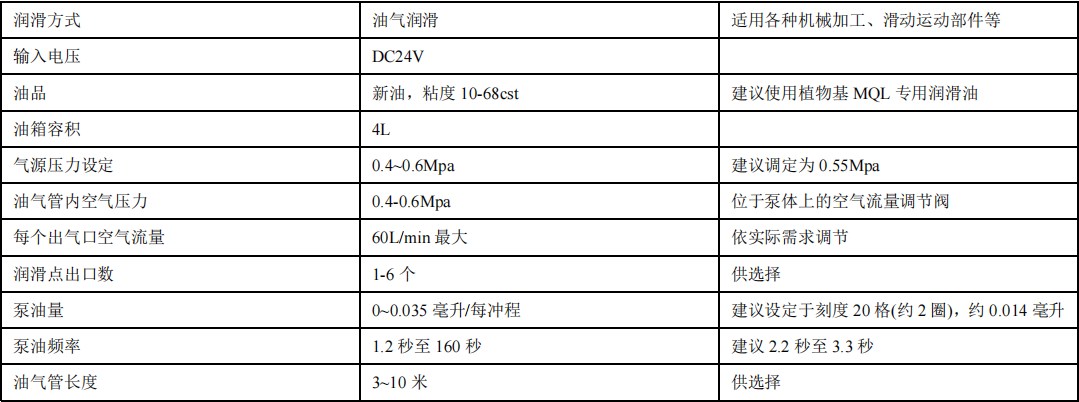

Specifications and parametersWhat is Micro Lubrication (MQL) and Low Temperature Micro Lubrication (CAMQL) :

Lubrication is a type of lubrication used in metal processing, i.e. semi-dry cutting. Lubrication is lubrication, where compressed gas (air, nitrogen, carbon dioxide, etc.) is mixed with Minimal Quantity Lubrication to form micron droplets. A cutting method that is sprayed into the processing area for effective lubrication. The amount of cutting fluid is generally only 0.03 ~ 0.4L/h(the amount of traditional wet cutting is 20 ~ 100L/min), which can effectively reduce the friction between the tool and the workpiece, the tool and the chip, prevent bonding, extend the tool life, and improve the quality of the machining surface. The so-called low-temperature CA-MQL refers to the spray of cold air mixed with oil below 0 degrees, the cold air is more effective in cooling and cooling, and the oil mist increases the lubrication effect, so as to achieve the purpose of cooling and cooling lubrication, which can effectively reduce the temperature of the machining tool, and produce lubrication effect, improve the service life of the tool, increase the surface quality of the workpiece, and the dry cutting can be truly realized.

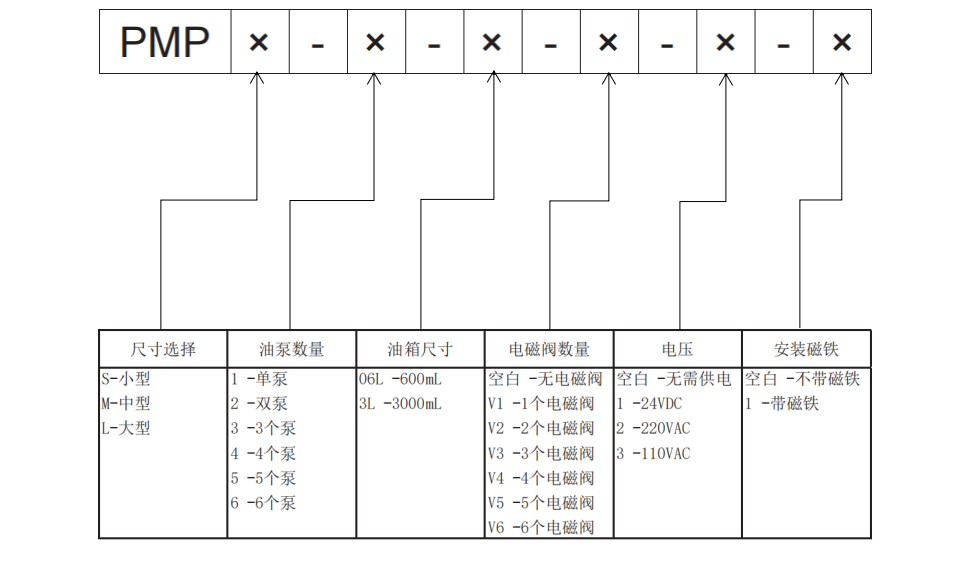

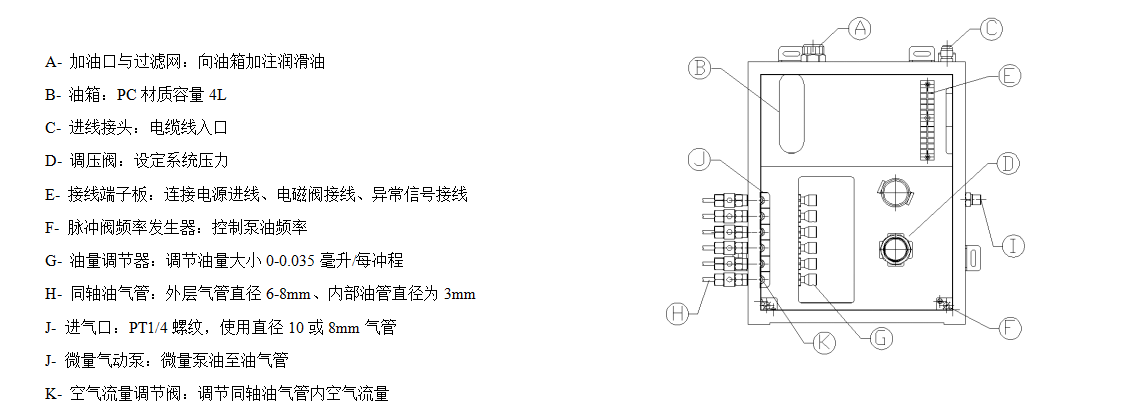

First, micro lubrication pump instructions:

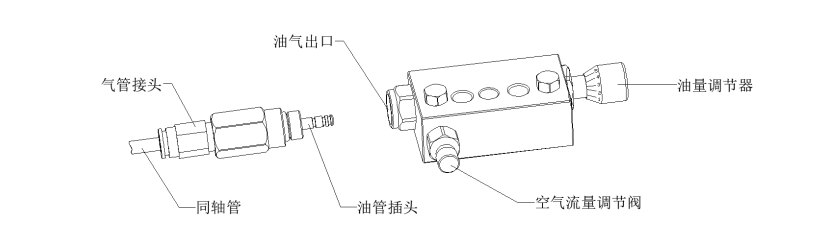

1. Micro pneumatic pump with frequency generator can pump out a trace of lubricating oil, the pumped oil into the oil coaxial tube in the small tubing, in the small tubing at the end of the flow and air flow control valve adjusted compressed air mixed, through the special nozzle to the cooling lubrication area, can be used for various mechanical processing, play a cooling lubrication, blowing the role of dust.

2. The number of pneumatic pumps can be combined according to demand, a single system can be combined with 6, and the pump oil volume of each pneumatic pump and the air flow of the oil and gas pipe can be adjusted separately.

3. The adjustment range of pump oil is 0~ 0.035ml/stroke, when the pump oil regulator rotates clockwise to the end, the oil amount is 0, when the counterclockwise rotation, each rotation of 10 grid scale is one circle, 10 grid oil amount is 0.007ml/stroke, the recommended value is 10~20 cells, adjust the oil amount according to the actual demand.

Ii. Precautions:

1. Oil products: Limit the use of clean oil products, oil products shall not have impurities, oil viscosity 10~68cst, shall not use recycled oil, water, etc., or corrosive liquids.

2. Use dry compressed air to avoid affecting the operation of the pneumatic pump.

3. The oil and gas coaxial pipe shall not be folded, which will affect the flow of lubricating oil and the accuracy of the pump oil.

4. The oil tank level should be higher than the lower limit of the liquid level switch.

To provide you with professional solutions