Line Vac is ideal for moving large amounts of material over long distances using minimal compressed air. The material flow can be easily controlled wi

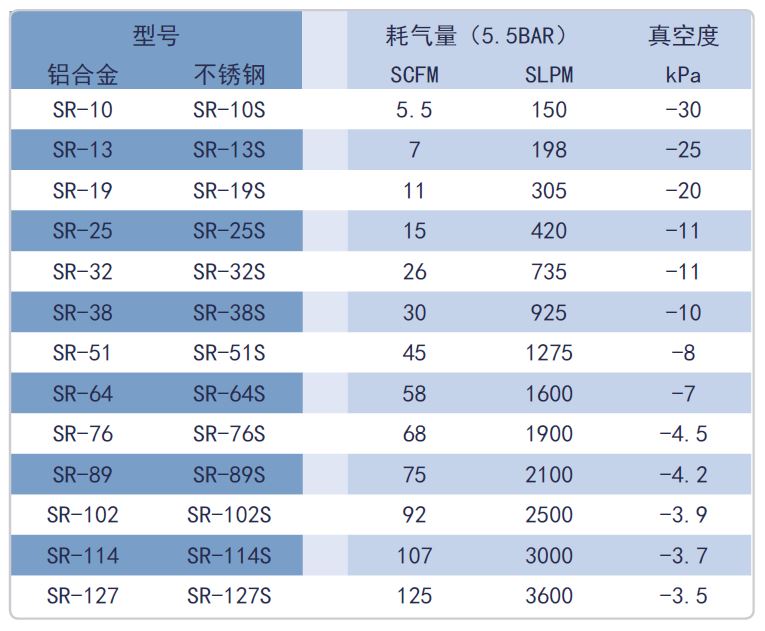

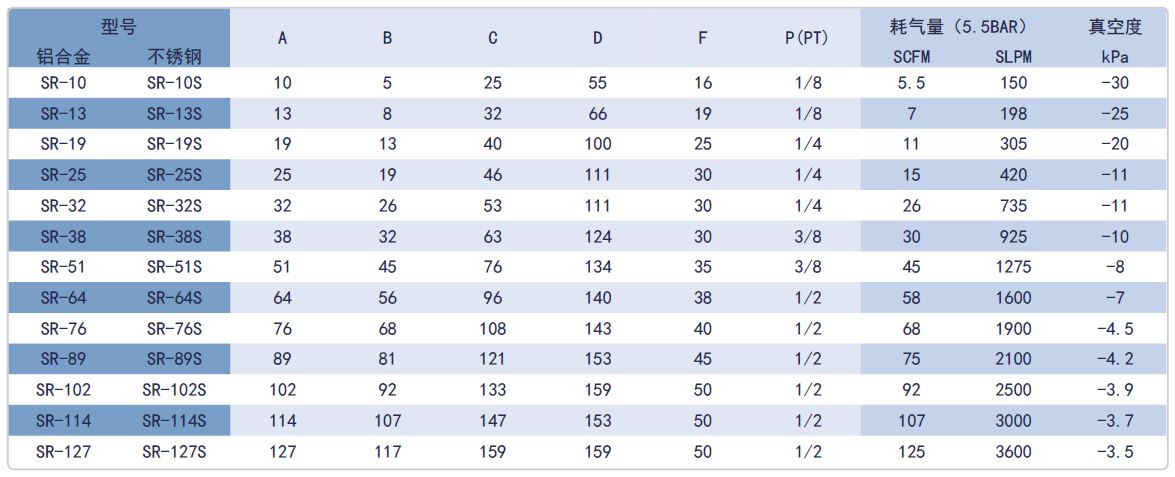

Specifications and parametersMany applications require materials to be transported over longer distances. Heavy-duty vacuums can move more material over longer lengths. They are designed for rugged industrial applications.

The flow rate through the pneumatic conveyor can be controlled by a pressure regulator, and the pressure regulator can be adjusted to suit the flow rate. Actual conveying rates are affected by the size, mass and geometry of the components to be conveyed, as well as the length, lift and number of bends in the hose, tube or pipe. These variables make it difficult to determine the exact conveying rate for any product, however, our application engineers can help you by comparing the material you want to convey to materials that have been tested.

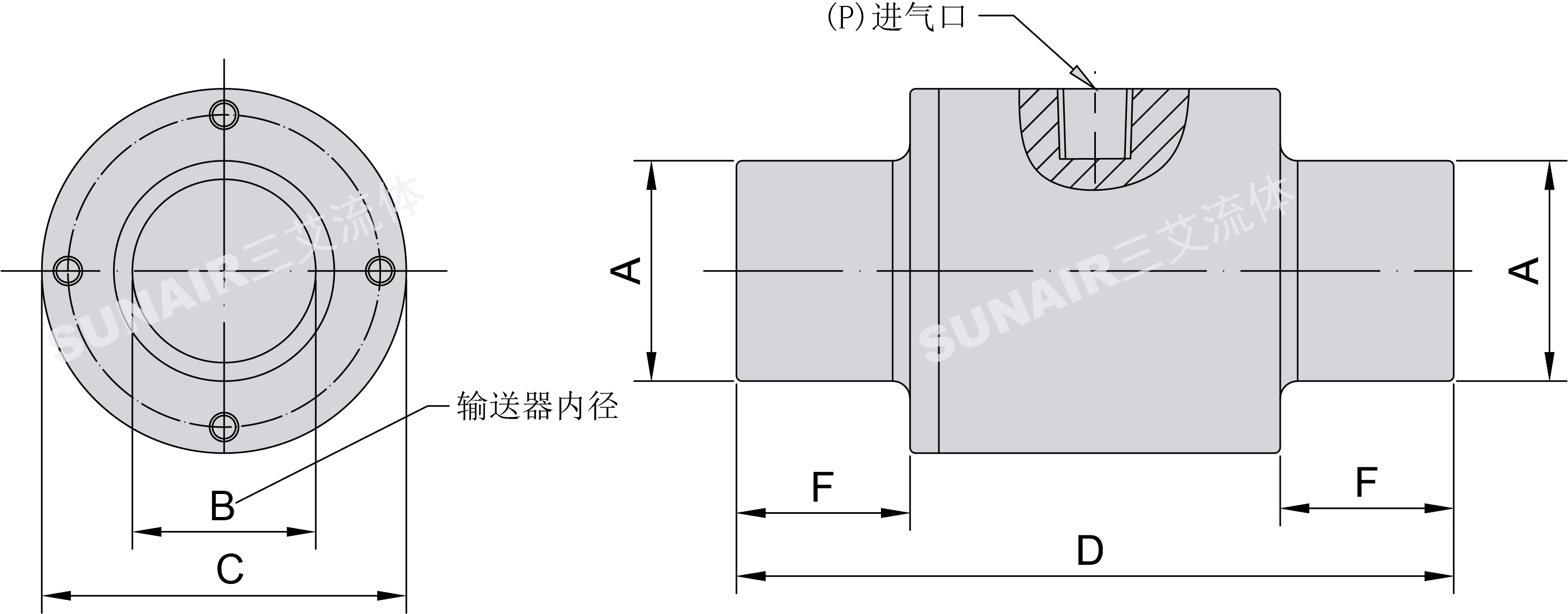

Working principle of pneumatic conveyor

After the compressed air enters the annular high-pressure chamber (2) through the air inlet (1), it flows through the nozzle (3) at high speed. This high-speed airflow passes through the inlet (4)

Low pressure is generated to form a vacuum, so the material at the inlet is sucked into the high-pressure airflow and transported to the designated position (5).

Application areas:

1- Hopper loading

2- Fiber tensioning

3- Material transportation

4- Scrap/Offcuts Removal

5- Chip removal

6- Parts transfer

7- Filling operation

Features:

1- Quiet

2- No moving parts

3- Fits standard hose or pipe

4- High throughput capability

5- Maintenance free

6- Aluminum or stainless steel

7- Durable-Stainless steel

8- Compact structure, small size, simple operation and easy installation

9- Different materials can be selected according to the working environment, such as copper, aluminum, stainless steel, high temperature alloy, etc.

To provide you with professional solutions