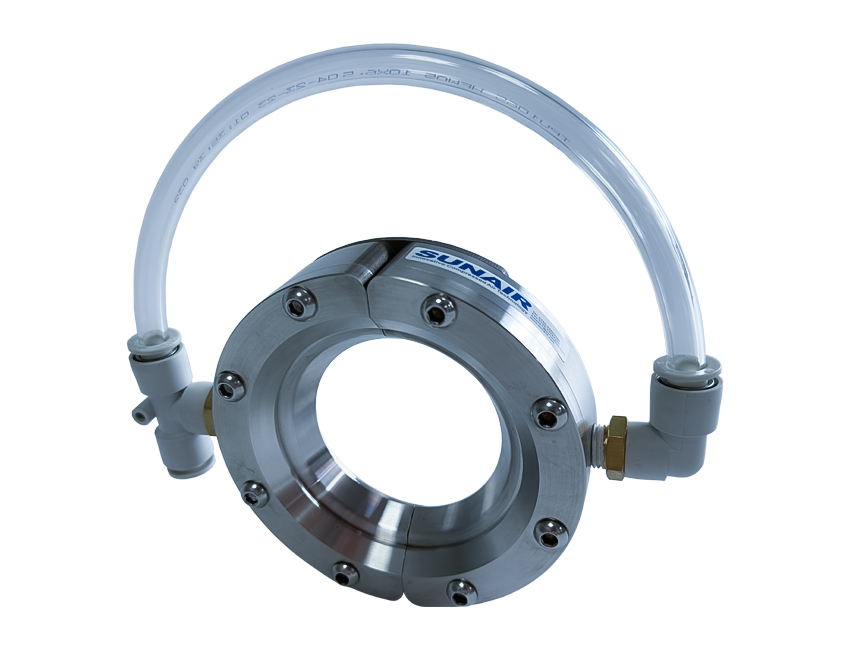

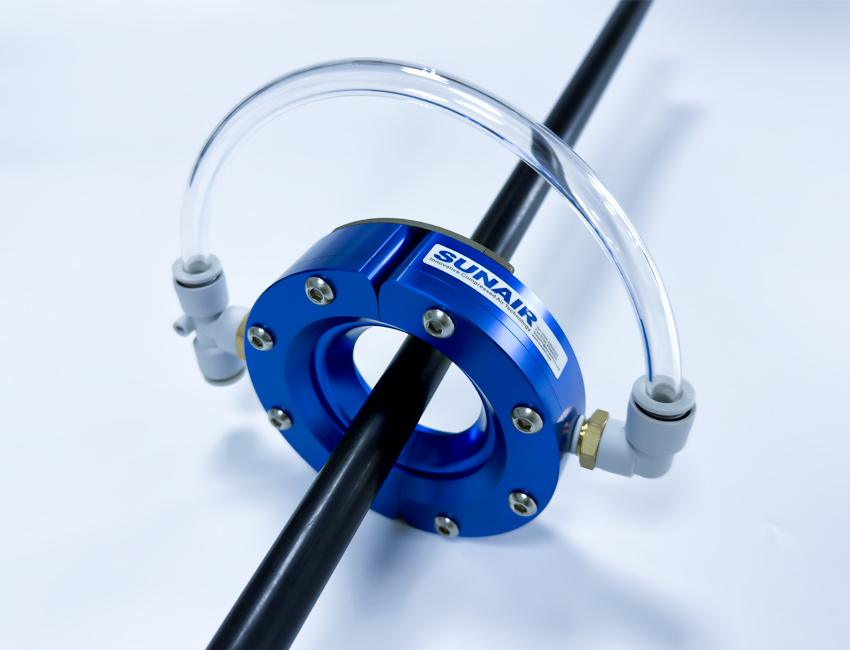

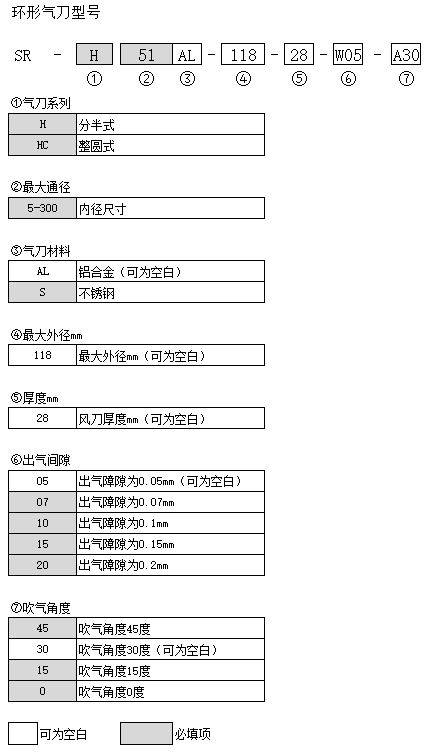

The SUNAIR Ring Blade provides an even 360 degree airflow and is ideal for blow drying, cleaning and cooling pipes, cables, extruded profiles, hoses,

Specifications and parametersThe SUNAIR annular air knife is also called an air scrubber. After the compressed air enters the air knife, the SUNAIR air knife passes through an air gap of about 0.02-0.08mm and blows it out at high speed with an air flow sheet. This primary air curtain can divert 40-50 times the ambient air to form a thin, high-strength, large-flow impact air curtain. Its air consumption is very small, but it can produce powerful blowing capabilities.

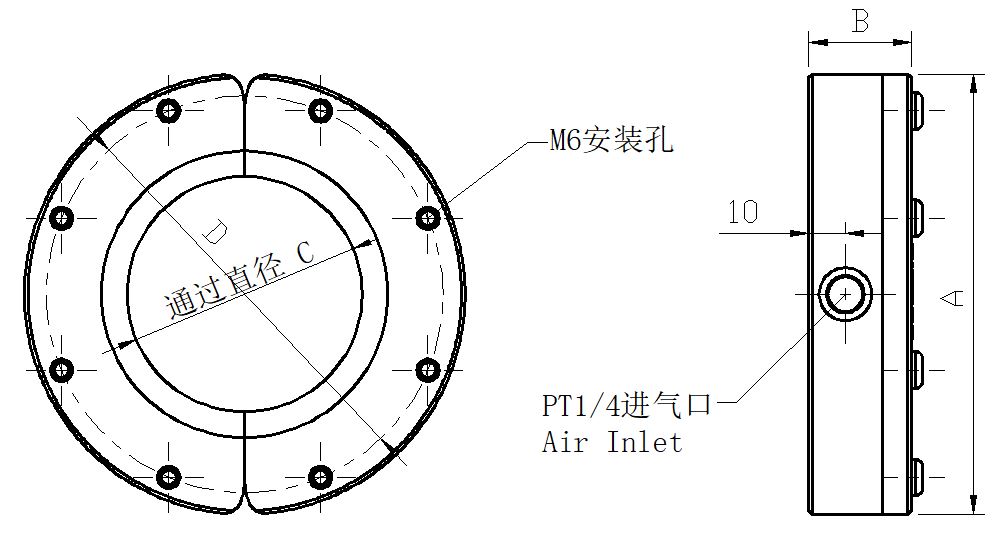

Air scrubber is a professional equipment used to blow, dry, clean and cool wires, metal wires, plastic pipes, metal pipes, cables and other linear materials, extruded products, hoses or other products. It provides uniform 360 ° annular airflow. The annular air knife is a split design, consisting of two large air knives, connected by two curved hinges. The split design can be directly opened and closed for long materials. Place the material in the middle without threading it through the head.

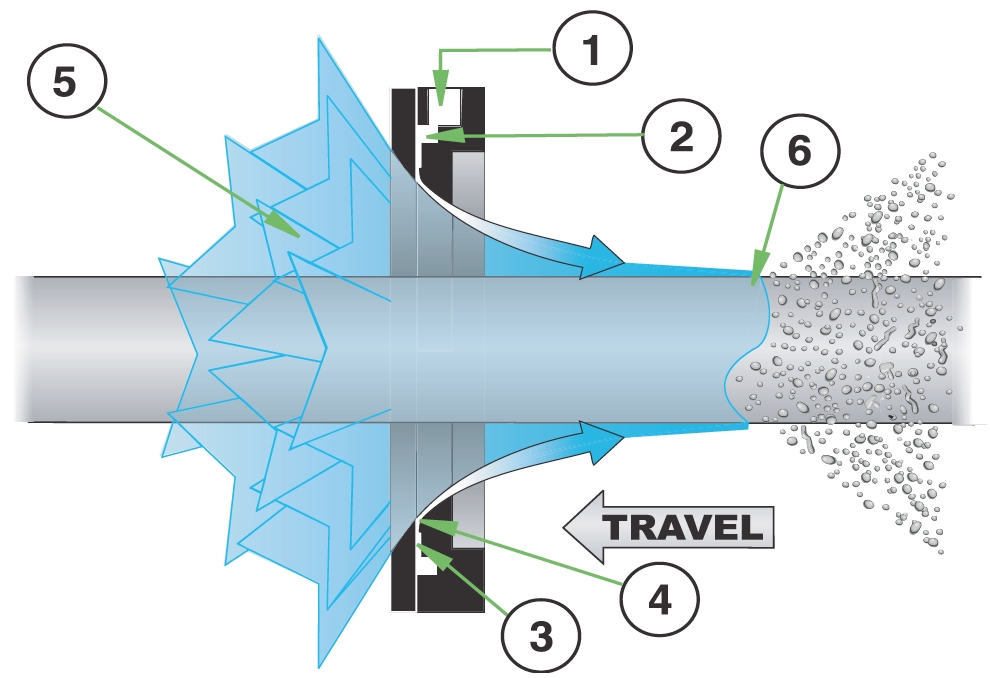

Principle of circular air knife:

The compressed air enters the annular cavity (2) through the inlet (1) , and then obtains a high-speed circulation through the annular nozzle (3) . The airflow is ejected at high speed along the side wall (4) , and this airflow is ejected at an oblique angle along the side wall of the air ring. In this way, a low-pressure area (5) will be generated in the center of one side of the air ring . This low-pressure area will force a large amount of surrounding air to flow to the other side of the air ring together with the high-pressure discharge air flow. When the airflow leaves the air ring, a 360 ° conical ring airflow is generated. This uniform and powerful airflow can continuously and stably blow away dirt, water and other impurities on the material (6) passing through the air ring.

application:

1- Cleaning and drying after plating or coating

2- Blow away dust and pollutants

3- Cool the hot extruded shape

4- Wipe the surface evenly

5- Steel extruded profiles, rods and medical hoses

6- Elimination solution-no cross contamination

7- Blow out excess water using car door gasket

8- Remove excess paint, water and oil

9- Steel pipes, hoses, wires, optical fibers

10- Minimize solution loss due to delays

11- Clean the paint

12- Stencil printing or inkjet surface

13- Ching Hao Strips and Ribbons

advantage:

1- Quiet and low noise

2- Low air consumption

3- 360 degree uniform airflow

4- Uniform airflow over the entire circumference

5- High temperature resistance

6- No moving parts, long service life

7- Contactless Qinghao

8- Split design-compact, sturdy and easy to install

9- Light weight

10- Comes with mounting holes

material selection:

Aluminum: Aluminum Super Air Knives are suitable for use in a variety of environments where corrosion or contamination factors are not present. The aircraft-grade aluminum construction with plastic spacers is durable and suitable for general use. The stainless steel screws used are corrosion-resistant. Its internal gaskets can withstand temperatures up to 82°C. If you need to withstand higher temperatures, the air outlet gap can be directly processed on the air knife, without a gasket, and can withstand high temperatures of 150°C.

Type 303 Stainless Steel: This is the most common grade of stainless steel. It has good strength and is best suited for mildly corrosive environments. In its gasketless form, it can withstand temperatures up to 427°C.

Type 304 stainless steel: Certain applications require better strength and corrosion resistance than Type 303 stainless steel. Type 304 stainless steel has excellent corrosion resistance and better strength properties and is also used by food manufacturers. It can withstand temperatures up to 427°C.

Type 316 Stainless Steel: Certain applications require better corrosion resistance than Type 304 stainless steel. Type 316 stainless steel offers excellent corrosion resistance, better strength properties and resistance to pitting corrosion. These factors are important to manufacturers of food, pharmaceutical and surgical products who need to minimize metal contamination. It can withstand temperatures up to 427°C.

To provide you with professional solutions